The Importance of HACCP

In the world of food, there are numerous opportunities for contamination. It doesn’t matter if you are raising animals or crops for consumption or are involved in harvesting, processing, transportation, distribution, and preparation.

Foodborne illnesses are one of the most widespread public health issues. Therefore, keeping customers safe is a top priority for any food-related business. For this reason, processes and systems have been developed and put into place to minimize risk to the consumer. Hazard Analysis and Critical Control Point (HACCP) is one process that has repeatedly shown itself to be an effective means of ensuring food safety.

Why was HACCP developed?

HACCP originated in the 1960s and was developed as a collaboration between the National Aeronautics and Space Administration (NASA), the Pillsbury Company, and the U.S. Army Laboratories to provide safe food for space expeditions.

Interestingly, it is believed to have stemmed from a production process monitoring used during World War II, when traditional “end of the pipe” testing on artillery shells firing mechanisms could not be performed.

What does HACCP do?

HACCP, a process control system, puts into place stringent protocols designed to prevent hazards from occurring. It identifies where hazards are likely in the food production process and when properly implemented, is central to an active food safety program.

By strict monitoring and control along each step of the process, there is less chance for hazards to occur. This provides assurance that your food safety program is professionally managed. For this reason, it is considered by the National Academy of Sciences, National Advisory Committee for Microbiological Criteria for Foods, and the Codex Alimentarius (the international food code established under the United Nations) the best process control system available.

The Value of HACCP Training Certification

HACCP certification is important because it demonstrates that an individual understands the HACCP process. This process helps pinpoint any microbiological, chemical, and/or physical contaminant that could impact food safety. By prioritizing and controlling potential hazards in food production, businesses protect their customers as well as their reputation.

The HACCP principles, aligned with the Federal Drug Administration’s Food Safety Modernization Act’s (FSMA) rule for processors, are the best platform from which to build an FSMA-compliant management system.

FMSA is a set of rules intended to prevent food-borne illnesses in U.S. food sources, with a focus on implementing a proactive approach to food safety.

Identifying potential hazards

By identifying and controlling potential hazards in raw materials, facility processes, and human error, HACCP programs offer the following benefits:

- Reduce the risk of foodborne illnesses

- Highlight high standards for food safety

- Quick and effective response to safety issues

- Increase revenue

- Provide legal protection through effective record keeping and proper documentation

- Increase business opportunity through compliance with international trade standards

- Help ensure trust in your product

HACCP Principles

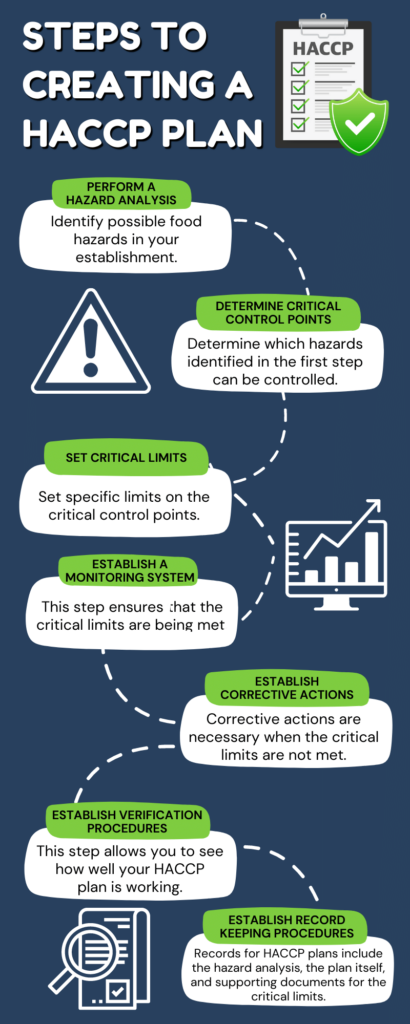

HACCP principles are part of a developed system ensuring that food is safe for consumption. Wherever you are in the food supply chain, following these seven principles will make safety a priority, guaranteeing the highest quality grade food preparation and production:

- Conduct a hazard analysis – this identifies potential hazards that could occur in production processes

- Identify the critical control points (CCPs) – these exist in the process where potential hazards could occur and best be prevented and/or controlled

- Establish critical limits – this assures there are preventive measures associated with each CCP

- Establish CCP monitoring requirements – thus ensuring each CCP stays within its limit as well as evaluating the process at CCPs

- Help establish corrective actions – when monitoring determines a CCP is not within the established limits

- Establish effective recordkeeping procedures – these document how the system is working

- Establish procedures for verifying – this assures everyone involved that your HACCP system is working properly

Education and Training

Adequate education and training are integral to the success of a HACCP system, since employees must first understand what HACCP is and then be given adequate time to learn skills critical to making the process function successfully. Specific training activities include working instructions and procedures that outline the tasks of each employee monitoring the CCPs.

HACCP certification is a process that reconciles your HACCP system to your documentation and the seven principles of HACCP. Because HACCP is an international system, certification must be acquired from a registered external certification body (see the FDA’s list of voluntary participants in its Accredited Third-Party Certification Program).

Employee certification vs business certification

A word of caution. Even though one (or more) of your employees has HACCP certification, this does not mean your business is certified. These are two vastly different things. Training involves:

- Understanding the requirements of HACCP – the first step is to complete training in the principles and application of HACCP. In the absence of in-house expertise, an external food safety consultant can assist.

- Developing a HACCP plan that is specific to your business – identify the system scope, including the areas, products, processes, and locations that your plan will cover (vital information to have when undergoing an audit).

- Conducting a gap analysis – if your business already has a HACCP plan, then a gap analysis is critical. This helps in identifying any HACCP standard that may have been overlooked. An external food safety consultant can help with this.

- And finally, before awarding certification – HACCP qualified auditors will conduct an audit. (Another word of caution is due here…it is up to the business seeking certification to ensure that the certification body has the requisite qualifications and accreditation.) The food safety audit may occur in two stages; a document review (which can be done remotely) and then an onsite review. Of course, follow-up may be required if any major issues are identified.

Final Thoughts

Implementing a HACCP-based food safety system and ensuring appropriate team members have been trained and certified can be the gateway to increased business opportunities.

As mentioned before, this can be achieved by demonstrating a commitment to food safety and ensuring the viability of your food business.

A HACCP system will make sure your products are always top-quality and you will also have the confidence of knowing that any time a health inspector knocks, you will be answering your door with the assurance that you are HACCP compliant.